We have a wealth of experience dealing with burners and other systems used on vessels: from boiler burners used for the main propulsion engine on large LNG carriers, to auxiliary boiler burners used as heat sources within the vessel, as well as waste liquid incinerators, and waste oil / sludge processing systems. We offer products with excellent energy savings and environmental performance in conjunction with a global service network in order to support safe and efficient marine transport.

Overview

Gas/Oil simultaneous mixed combustion DF (Dual Fuel, which means gas and oil) burner for boiler of LNG (Liquefied Natural Gas) fueled vessel "Vignis" has Gas/Oil simultaneous mixed combustion mode as well as HFO-mono, MGO-mono and LNG-mono combustion mode.

Gas/Oil simultaneous mixed combustion mode can efficiently utilize BOG as fuel and shortage of calorie can be fulfilled by “Fuel Oil”. Because combustion condition is stable even at Gas/Oil simultaneous mixed combustion mode and fuels can be easily changed over,and also it is useful in preventing human error.

The new "Vignis" equips GCU mode. And a boiler which is equipped "Vignis" can be used as GCU(gas combustion unit).

Also, the wide range type is possible to process more boil off gases.

Specification of Vignis

- Evaporation rate: For 1.0 to 7.0 t/h

- HFO Max. Combustion Rate: 100 to 600 kg/h

- MGO Max. Combustion Rate: 95 to 565 kg/h

- Gas Max. Combustion Rate: 80 to 480 kg/h

- Turndown ratio(gas): 10:1

- Combustion configuration: Gas / Oil simultaneous mixed combustion, single-fuel gas combustion, single-fuel oil combustion

- Spray method: Gas / Diffusive mixing, Oil / Air spraying

- Control method: Proportional control

- Compatible fuel: HFO, MGO and LNG

- Fuel viscosity: Supports 700 cSt

Specification of Vignis-W (wide range type)

- Evaporation rate: For 1.0 to 2.0 t/h

- HFO Max. Combustion Rate: 100 to 190 kg/h

- MGO Max. Combustion Rate: 95 to 180 kg/h

- Gas Max. Combustion Rate: 80 to 150 kg/h

- Turndown ratio(gas): 10:1

- GCU mode

Gas Max. Combustion Rate: 240 to 450 kg/h - Wide range type (Vignis-W)

Gas combustion amount for GCU mode is three times higher capacity than normal operation.

That can reduce working hours when LNG fueled vessels and bunkering vessels are gas freeing.

Features

- Gas/Oil simultaneous mixed combustion

Fuel can be changed automatically and safely because it is capable of burning Gas and Oil simultaneously.

"Vignis" contributes to zero methane gas release into the atmosphere because it equips GCU mode by the simultaneous mixed combustion. - GCU mode

All types of "Vignis" equips GCU mode as a standard specification in addition to the boiler mode.

It contributes to simplify device configuration and in some cases, no need to install GCU by using GCU mode. - Combusts gas of any ratio

"Vignis" is capable of treating inert gas up to 100% content due to Gas/Oil simultaneous mixed combustion. - Wide turndown ratio “10:1”

"Vignis" reduces heat loss by decreasing frequency of both firing and extinguishing due to wide range Turndown Ratio up to 10:1 - Compatible with a wide range boilers

"Vignis" is applicable to boilers with evaporation rate of 1 to 7t/h

Gas/Oil simultaneous mixed combustion DF burner “SFFGⅡ”

can be used for boilers which evaporation rate is higher than 7t/h. - Completely compliant with international standard IGF code*1 and IGC code*2

Based on 38 years of experience in gas combustion on vessels,Volcano DF burner is completely compliant with international standard IGF code and IGC code.

Remarks;

*1 IGF CODE : International Code Of Safety for the ships using Gases Or other Low-Flash Point Fuels.

International standards applicable to LNG fueled ships.

*2 IGC CODE : International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk.

International standards applicable to LNG carriers.

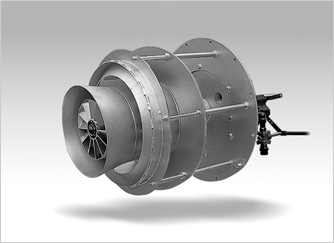

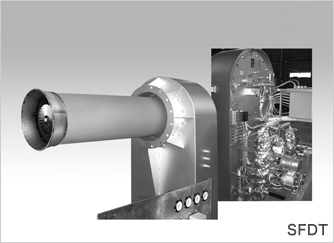

Overview

This burner uses proportional control for efficiency and energy savings. It not only supports heavy oil (HFO) but can also be used with a variety of oils, including MGO that is compliant with SOx regulations. This compact, packaged burner integrates the fuel pump, heater, fan and other components all into one unit.

Specification

- Evaporation rate: For 1.0 to 3.0 t/h

- Oil combustion capacity: 90 to 250 kg/h

- Turndown ratio: 3:1

- Spray method: Hydraulic spraying

- Control method: Proportional control

- Compatible fuel: HFO, MGO and MDO

- Fuel viscosity: Supports 700 cSt

Features

- This burner offers proportional control with a turndown ratio of 3:1 and energy saving operation.

- The switch type supports HFO/MGO.

- It uses flexible tubing to simplify sprayer maintenance.

- It supports combustion for a variety of oils, from MGO to heavy oil with a viscosity of 700 cSt.

- This compact, packaged burner integrates the fuel pump, heater, fan and other components all into one unit.

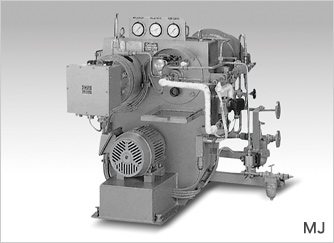

Overview

This burner was designed and developed for small auxiliary boilers and composite boilers. It not only supports heavy oil (HFO) but can also be used with a variety of oils, including MGO that is compliant with SOx regulations. The MJ type was launched in 1977 and the MJ II, based on the performance of the MJ, has become our best seller after being launched in 2008.

Specification

- Evaporation rate: For 1.0 to 3.0 t/h

- Oil combustion capacity: 90 to 250 kg/h

- Turndown ratio: 1:1 and 2:1

- Spray method: Hydraulic spraying

- Control method: ON / OFF control, and ON / OFF + HI / LOW control

- Compatible fuel: HFO, MGO, MDO, (W.O: option)

- Fuel viscosity: Supports 700 cSt

Features

- The simple design makes maintenance easy.

- It uses flexible tubing to simplify sprayer maintenance.

- It supports combustion for a variety of oils, from MGO to heavy oil with a viscosity of 700 cSt.

- This compact, packaged burner integrates the fuel pump, heater, fan and other components all into one unit.

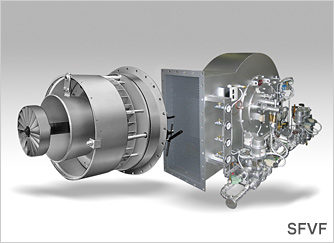

Overview

This burner is equipped with automatic combustion control (ACC) as well as various attachments, such as a window box, pilot burner and fuel shut-off valve. It uses a vapor spraying method, which can support the tightening of regulations (for NOx and SOx, etc.) in the future by replacing the atomizer. It not only supports heavy oil (HFO) but can also be used with a variety of oils, including MGO that is compliant with SOx regulations. Combustion for waste oil is also possible by adding a sprayer as an option.

Specification

- Evaporation rate: For 1.0 to 10.0 t/h

- Oil combustion capacity: 90 to 850 kg/h

- Turndown ratio: 2.5:1 to 6:1

- Spray method: Vapor spraying

- Control method: ON / OFF control, and ON / OFF + HI / LOW control

- Compatible fuel: HFO, MGO, MDO, (W.O: option)

- Fuel viscosity: Supports 700 cSt

Features

- This is a compact and semi-packaged burner.

- It supports combustion for a variety of oils, from MGO to heavy oil with a viscosity of 700 cSt.

- It has a large turndown ratio and supports energy saving operation.

(Evaporation rate 1.0 to 3.0 t/h with 2.5:1 turndown ratio / Evaporation rate 4.0 to 6.0 t/h with 5:1 turndown ratio / Evaporation rate 8.0 to 10.0 t/h with 6:1 turndown ratio) - Combustion for waste oil is also possible by adding a sprayer as an option.

Overview

This “Energy Saving Burner” is our environmentally friendly burner. It supports a wide range of low oxygen conditions, contributing to energy savings as well as reducing the impact on the environment. It uses a vapor spraying method, which can support the tightening of regulations (for NOx and SOx, etc.) in the future by replacing the atomizer. It not only supports heavy oil (HFO) but can also be used with a variety of oils, including MGO that is compliant with SOx regulations.

Specification

- Evaporation rate: For 20.0 to 55.0 t/h

- Oil combustion capacity: 1,660 to 4,500 kg/h

- Turndown ratio: 15:1

- Spray method: Vapor spraying

- Control method: Proportional control

- Compatible fuel: HFO, MGO, MDO and crude oil

- Fuel viscosity: Supports 700 cSt

Features

- It supports a wide range of low oxygen conditions (boiler load ratio 20 to 100% when O2 is 2.0%).

- Energy savings and reduced environmental impact (low O2, low NOx and low dust and particulates).

- Energy saving operation is possible with a turndown ratio of 15:1 (evaporation rate 20.0 to 55.0 t/h).

- Combine it with a small capacity atomizer to achieve a 25:1 turndown ratio and even greater energy savings.

- Single and multiple burner configurations are available (Multi-burners for a boiler available).

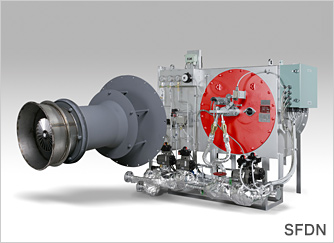

Overview

These burners are used on large boilers and has a simple design for easy maintenance. It uses a vapor spraying method, which can support the tightening of regulations (for NOx and SOx, etc.) in the future by replacing the atomizer. It not only supports heavy oil (HFO) but can also be used with a variety of oils, including MGO that is compliant with SOx regulations. This large boiler burner can support single and multiple burner configurations (multi-type available).

Specification

- Evaporation rate: For 20.0 to 55.0 t/h

- Oil combustion capacity: 1,750 to 4,750 kg/h

- Turndown ratio: 10:1

- Spray method: Vapor spraying

- Control method: Proportional control

- Compatible fuel: HFO, MGO, MDO and crude oil

- Fuel viscosity: Supports 700 cSt

Features

- It supports low oxygen operation (O2 is 2.8%) and stable combustion despite low flow pressure.

- With a turndown ratio of 10:1, it offers energy saving operation and supports extreme load variation in boilers.

- It uses a vapor spraying method, which can support the tightening of regulations (for NOx and SOx, etc.) in the future by replacing the atomizer.

- Combine it with a small capacity atomizer to achieve a 19:1 turndown ratio and even greater energy savings.

- Single and multiple burner configurations are available (Multi-burners for a boiler available).